Graphite Electrode Scrap Sida Kaarboon koriyaha Recarburizer Steel Casting Industry

Qiyaasta Farsamada

| Shayga | iska caabin | Cufnaanta Dhabta ah | FC | SC | Dambas | VM |

| Xogta | ≤90μΩm | ≥2.18g/cm3 | ≥98.5% | ≤0.05% | ≤0.3% | ≤0.5% |

| Ogow | 1.The size iibinta ugu fiican waa 0-20mm, 0-40, 0.5-20,0.5-40mm iwm. | |||||

| 2.Waxaan burburin karnaa oo baari karnaa sida waafaqsan shuruudaha macaamiisha. | ||||||

| 3.Tiro weyn iyo karti sahayda deggan sida waafaqsan shuruudaha gaarka ah ee macaamiisha | ||||||

Waxqabadka xoqida Graphite Electrode

- Waxyaabaha kaarboonka sarreeya

- Maadada baaruudka oo hooseeya

- daahirnimo sare

- Arrin kacsan oo sarreeya

- Dambas hooseeya

- Cufnaanta sare

Sharaxaada

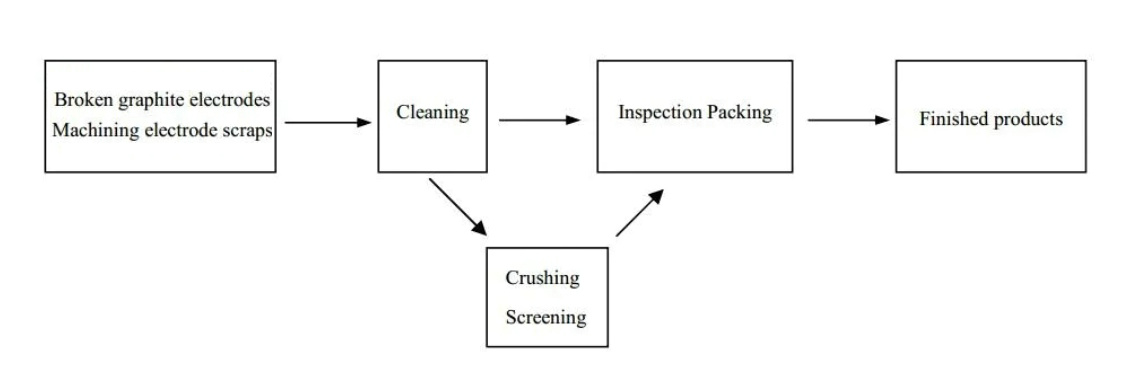

Iskaraabka korantada graphite waxa uu ka imanayaa electrodes graphite jabay,machining electrode scraps.We ururin,burburin,baaro iyo baakadaha ugu dambeyntii la gaarsiiyo macaamiisha.

Iskaraabka korantada graphite waxa caadi ahaan loo isticmaalaa samaynta birta, warshadaha biraha sida kaarboon-kiciya, wax-yareeya, wax ka beddelka, kaarboonka lagu daro, iyo walxaha dab-demiska.

Iskaraabka graphite electrode waxaa lagu heli karaa cabbirro kala duwan, oo ay ku jiraan budada iyo granules, taasoo ka dhigaysa mid ku habboon codsiyada kala duwan oo ka dhigaysa mid aad u badan. Foomka budada ah wuxuu ku habboon yahay in lagu daro birta dhalaalaysa, halka granules loo isticmaali karo diyaarinta birta iyo qalabka wax lagu shubo. Kala duwanaanshiyahani wuxuu bixiyaa dabacsanaan iyo raaxaysi, hubinta in soosaarayaashu ay ku shaqeyn karaan walxaha sida ay doorbidayaan iyo shuruudaha.

Maaddooyinka sare ee kaarboonka ee qashinka graphite electrode waxay hubisaa waxtarka kor u qaadista sifooyinka birta iyo alaabta tuurista. Waxa kale oo ay leedahay sifooyin kulayl oo aad u fiican, taas oo ka dhigaysa mid ku habboon in loo isticmaalo foornooyinka arc koronto. Qalabka gaarka ah ayaa si weyn loogu isticmaalay kordhinta kaarboonka ee birta iyo birta birta sanado badan, waxayna noqotay mid sii kordheysa oo caan ah sababtoo ah faa'iidooyinka guud ee waxqabadka.

Habka Alaabta

Codsiga

1. Sida alaabta ceeriin ee soo saarta electrodes kaarboonka iyo kaarboonka kaarboonka

2. Sida kaarboonka lagu daro, kaarboon-kiciya, kaarboonizer samaynta birta iyo aasaaska

- Lagu soo buuxiyay bacaha tolmada leh ama sida waafaqsan shuruudaha macaamiisha ama baakadaha dabacsan

- Kaarboon Kaarboon Gufan waxay xakameysaa nidaam kasta si loo hubiyo tayada adag ee alaabada si loo qanciyo shuruudaha macaamiisha.

- Kaarboonka Gufan wuxuu bixiyaa cabbirro kala duwan oo badeecado ah oo ay ku jiraan budada iyo granules. Dhammaan alaabooyinka waxaa lagu soo saari karaa si waafaqsan shuruudaha macaamiisha.

Dammaanadda Qancinta Macmiilka

Dukaankaaga "Hal-Stop-Shop" ee GRAPHITE ELECTRODE oo ah qiimaha ugu hooseeya ee la dammaanad qaaday

Laga bilaabo wakhtiga aad la xidhiidho Gufan, kooxdayada khubarada ah waxaa ka go'an inay bixiyaan adeeg heersare ah, alaabo tayo leh, iyo keenista wakhtiga ku haboon, waxaanan garab taaganahay badeecad kasta oo aanu soo saarno.

Adeegyada macaamiisha GUFAN waxaa ka go'an in ay bixiyaan adeeg macmiil oo gaar ah heer kasta oo ka mid ah isticmaalka alaabta,Kooxdeena waxay taageertaa dhammaan macaamiisha si ay u gaaraan yoolalkooda hawleed iyo maaliyadeed iyada oo loo marayo bixinta taageerada muhiimka ah ee meelaha muhiimka ah.