UHP 500mm Dia 20 inch Furnace Electrode oo leh ibta naaska

Qiyaasta Farsamada

Qalabka Jirka & Kiimikada D500mm(20 ") Electrode & Ibta Naaska

| Halbeegga | Qayb | Unug | UHP 500mm(20 ") Xog |

| Dhexroor Magaca | Electrode | mm (inji) | 500 |

| Dhexroorka ugu badan | mm | 511 | |

| Dhexroor Min | mm | 505 | |

| Dhererka magacaaban | mm | 1800/2400 | |

| Dhererka ugu badan | mm | 1900/2500 | |

| Dhererka min | mm | 1700/2300 | |

| Cufnaanta ugu badan ee hadda | KA/cm2 | 18-27 | |

| Awood Qaadashada Hadda | A | 38000-55000 | |

| Iska caabin gaar ah | Electrode | μΩm | 4.5-5.6 |

| Ibta naaska | 3.4-3.8 | ||

| Xoog Jilicsan | Electrode | Mpa | ≥12.0 |

| Ibta naaska | ≥22.0 | ||

| Modulka dhalinyarada | Electrode | Gpa | ≤13.0 |

| Ibta naaska | ≤18.0 | ||

| Cufnaanta Bulk | Electrode | g/cm3 | 1.68-1.72 |

| Ibta naaska | 1.78-1.84 | ||

| CTE | Electrode | ×10-6/℃ | ≤1.2 |

| Ibta naaska | ≤1.0 | ||

| Waxyaabaha Dambaska ah | Electrode | % | ≤0.2 |

| Ibta naaska | ≤0.2 |

FIIRO GAAR AH: Shuruudaha gaarka ah ee cabbirka waa la bixin karaa.

Codsiyada

- Foornada Arc Koronto

Electrode-ka graphite ayaa inta badan loo adeegsadaa habka birta samaynta ee casriga ah, Foornada Korontada ee Arc waxaa si weyn loogu aqoonsan yahay mid ka mid ah aaladaha ugu waxtarka badan uguna kalsoonida badan. Foornada arc koronto waxay isticmaashaa electrodes graphite si ay u abuurto heerkul sare oo ay dhaliso hadda, kaas oo markaa loo isticmaalo in lagu dhalaaliyo qashinka dib loo warshadeeyay. Maaddaama dhexroorka korantada graphite ay door muhiim ah ka ciyaarto abuurista heerka kuleylka lagama maarmaanka ah iyo hubinta tayada dhamaadka tayada sare, adeegsiga korantada saxda ah ayaa muhiim u ah helitaanka natiijooyinka ugu wanaagsan. Marka loo eego awoodda foornada korantada, korantada graphite dhexroorka kala duwan ayaa lagu qalabeeyaa si loo sameeyo korantada graphite-ka sii wadida isticmaalka, electrode graphite waxay ku xiran yihiin ibta naaska. - Foornada Korontada ee quusta

Foornada Korontada ee hooseysa waa wax soo saar kacaan ah oo loogu talagalay in lagu daboolo baahiyaha warshadaha casriga ah. Foornadan casriga ah waxay leedahay graphite electrode UHP kaas oo si gaar ah loo farsameeyay si loo hagaajiyo waxtarka habka dhalaalka. Electrode-ka graphite-ka ee ku jira foornada Korontada ee hooseysa waxaa inta badan loo isticmaalaa in lagu soo saaro ferroalloys, silicon saafi ah, fosfooraska jaalaha ah, matte iyo kaarbiid calcium. Naqshadaynta gaarka ah ee foornadan korontada ayaa ka dhigaysa foornooyinka dhaqanka, maadaama ay u oggolaanayso qayb ka mid ah korantada korantada in lagu aaso alaabta wax lagu dallaco. - Foornada iska caabinta

Foornooyinka iska caabinta waxaa loo isticmaalaa in lagu soo saaro alaab garaafeed tayo sare leh sida UHP graphite electrodes. Electrodes-yadan ayaa si weyn loogu isticmaalaa habka birta foornada foornada korontada si ay u soo saaraan birta waxqabadka sare leh. UHP graphite electrode waxaa lagu yaqaanaa kuleylkeeda sare, iska caabin koronto oo hooseeya, iyo iska caabin shoogga kulaylka. Guryahani waxay ka dhigaan doorasho ku habboon habka birta samaynta. Electrodes graphite UHP waxaa soo saara habka garaafaynta heerkulka sare ee foornada iska caabinta.

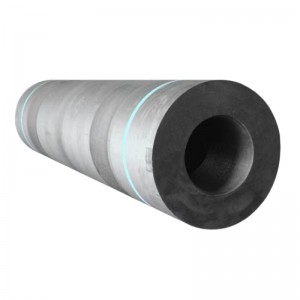

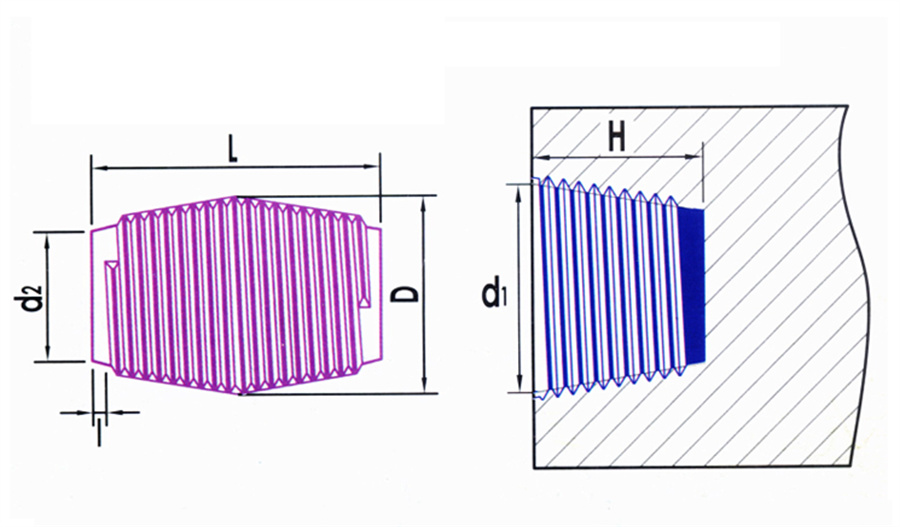

Gufan Cabon Ibta Koontada ah iyo Sawirka Socket

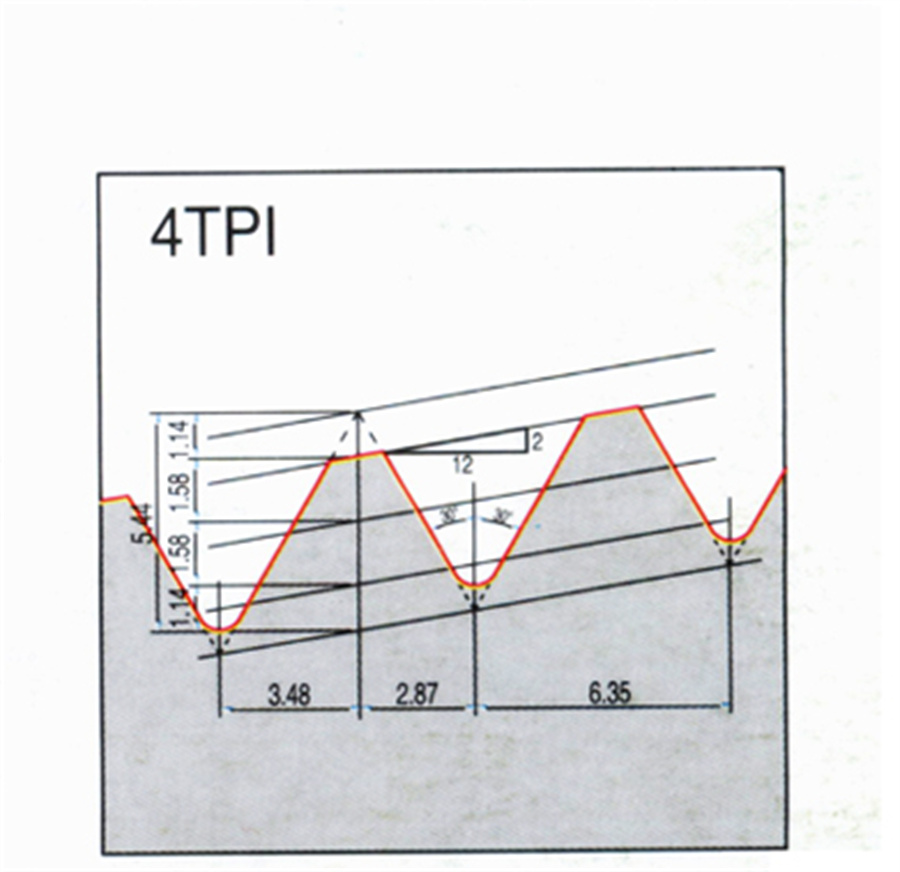

Kaarboon Kaarboon Gufan Ibta Naasaha iyo Cabbirrada Socket (4TPI)

| Kaarboonka Gufan ee ibta naasaha ah iyo cabbirrada godka (4TPI) | |||||||||

| Dhexroor Magaca | Koodhka IEC | Cabirka ibta naaska (mm) | Cabirka Socket(mm) | Dulqaad | |||||

| mm | inji | D | L | d2 | I | d1 | H | mm | |

| Dulqaad (-0.5~0) | Dulqaadasho (-1~0) | Dulqaadasho (-5~0) | Dulqaadasho (0~0.5) | Dulqaadasho (0~7) | |||||

| 200 | 8 | 122T4N | 122.24 | 177.80 | 80.00 | <7 | 115.92 | 94.90 | 6.35 |

| 250 | 10 | 152T4N | 152.40 | 190.50 | 108.00 | 146.08 | 101.30 | ||

| 300 | 12 | 177T4N | 177.80 | 215.90 | 129.20 | 171.48 | 114.00 | ||

| 350 | 14 | 203T4N | 203.20 | 254.00 | 148.20 | 196.88 | 133.00 | ||

| 400 | 16 | 222T4N | 222.25 | 304.80 | 158.80 | 215.93 | 158.40 | ||

| 400 | 16 | 222T4L | 222.25 | 355.60 | 150.00 | 215.93 | 183.80 | ||

| 450 | 18 | 241T4N | 241.30 | 304.80 | 177.90 | 234.98 | 158.40 | ||

| 450 | 18 | 241T4L | 241.30 | 355.60 | 169.42 | 234.98 | 183.80 | ||

| 500 | 20 | 269T4N | 269.88 | 355.60 | 198.00 | 263.56 | 183.80 | ||

| 500 | 20 | 269T4L | 269.88 | 457.20 | 181.08 | 263.56 | 234.60 | ||

| 550 | 22 | 298T4N | 298.45 | 355.60 | 226.58 | 292.13 | 183.80 | ||

| 550 | 22 | 298T4L | 298.45 | 457.20 | 209.65 | 292.13 | 234.60 | ||

| 600 | 24 | 317T4N | 317.50 | 355.60 | 245.63 | 311.18 | 183.80 | ||

| 600 | 24 | 317T4L | 317.50 | 457.20 | 228.70 | 311.18 | 234.60 | ||