Graphite Electrodes Ibta Naasaha 3tpi 4tpi Isku Xidhka Pin T3l T4l

Sharaxaada

Ibta graphite electrode waa qayb yar laakiin lama huraan u ah habka birta samaynta EAF.Waa qayb qaabaysan oo isku xidha korantada iyo foornada.Inta lagu jiro habka birta samaynta, korantada waxaa lagu dejiyaa foornada waxaana lagu dhejiyaa taabashada birta dhalaalaysa.Hadda korontadu waxay dhex maraa korantada, taasoo dhalisa kulayl, kaas oo dhalaaliya birta foornada.Ibta naasku waxay door muhiim ah ka ciyaartaa ilaalinta xidhiidhka korantada ee u dhexeeya korantada iyo foornada.

Qiyaasta Farsamada

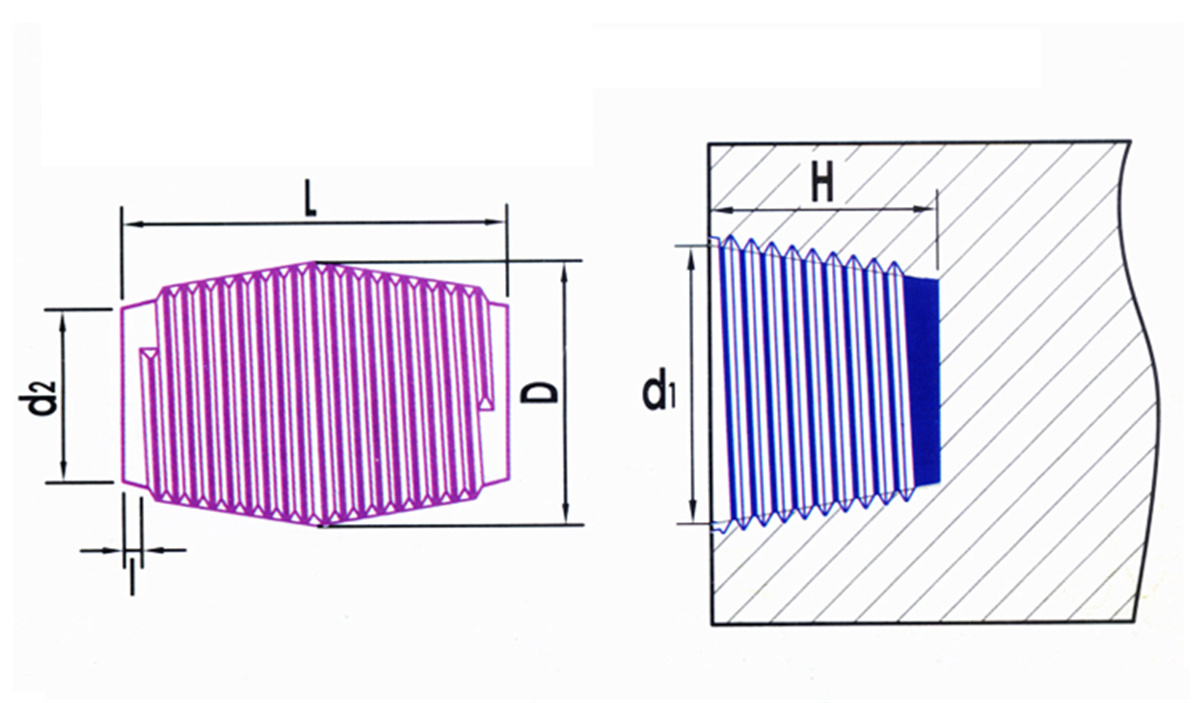

Sawirka Ibta Conical ee Kaarboon Gufan iyo Sawirka

| Dhexroor Magaca | Koodhka IEC | Cabirka ibta naaska (mm) | Cabirka Socket(mm) | Garoon | |||||

| mm | inji | D | L | d2 | I | d1 | H | mm | |

| Dulqaad (-0.5~0) | Dulqaadasho (-1~0) | Dulqaadasho (-5~0) | Dulqaadasho (0~0.5) | Dulqaadasho (0~7) | |||||

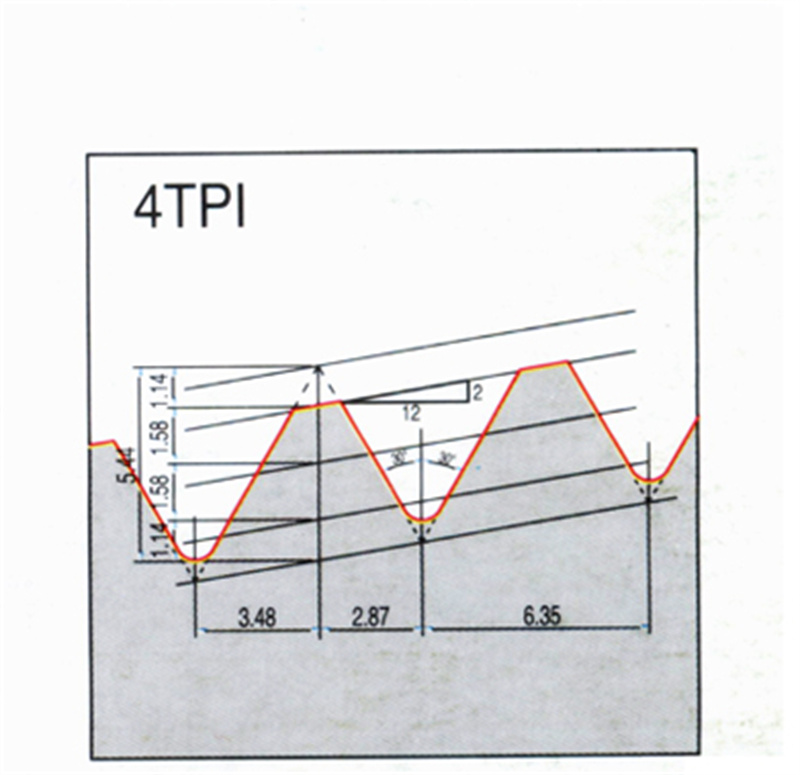

| 200 | 8 | 122T4N | 122.24 | 177.80 | 80.00 | <7 | 115.92 | 94.90 | 6.35 |

| 250 | 10 | 152T4N | 152.40 | 190.50 | 108.00 | 146.08 | 101.30 | ||

| 300 | 12 | 177T4N | 177.80 | 215.90 | 129.20 | 171.48 | 114.00 | ||

| 350 | 14 | 203T4N | 203.20 | 254.00 | 148.20 | 196.88 | 133.00 | ||

| 400 | 16 | 222T4N | 222.25 | 304.80 | 158.80 | 215.93 | 158.40 | ||

| 400 | 16 | 222T4L | 222.25 | 355.60 | 150.00 | 215.93 | 183.80 | ||

| 450 | 18 | 241T4N | 241.30 | 304.80 | 177.90 | 234.98 | 158.40 | ||

| 450 | 18 | 241T4L | 241.30 | 355.60 | 169.42 | 234.98 | 183.80 | ||

| 500 | 20 | 269T4N | 269.88 | 355.60 | 198.00 | 263.56 | 183.80 | ||

| 500 | 20 | 269T4L | 269.88 | 457.20 | 181.08 | 263.56 | 234.60 | ||

| 550 | 22 | 298T4N | 298.45 | 355.60 | 226.58 | 292.13 | 183.80 | ||

| 550 | 22 | 298T4L | 298.45 | 457.20 | 209.65 | 292.13 | 234.60 | ||

| 600 | 24 | 317T4N | 317.50 | 355.60 | 245.63 | 311.18 | 183.80 | ||

| 600 | 24 | 317T4L | 317.50 | 457.20 | 228.70 | 311.18 | 234.60 | ||

| 650 | 26 | 355T4N | 355.60 | 457.20 | 266.79 | 349.28 | 234.60 | ||

| 650 | 26 | 355T4L | 355.60 | 558.80 | 249.66 | 349.28 | 285.40 | ||

| 700 | 28 | 374T4N | 374.65 | 457.20 | 285.84 | 368.33 | 234.60 | ||

| 700 | 28 | 374T4L | 374.65 | 558.80 | 268.91 | 368.33 | 285.40 | ||

| Dhexroor Magaca | Koodhka IEC | Cabirka ibta naaska (mm) | Cabirka Socket(mm) | Garoon | |||||

| mm | inji | D | L | d2 | I | d1 | H | mm | |

| Dulqaad (-0.5~0) | Dulqaadasho (-1~0) | Dulqaadasho (-5~0) | Dulqaadasho (0~0.5) | Dulqaadasho (0~7) | |||||

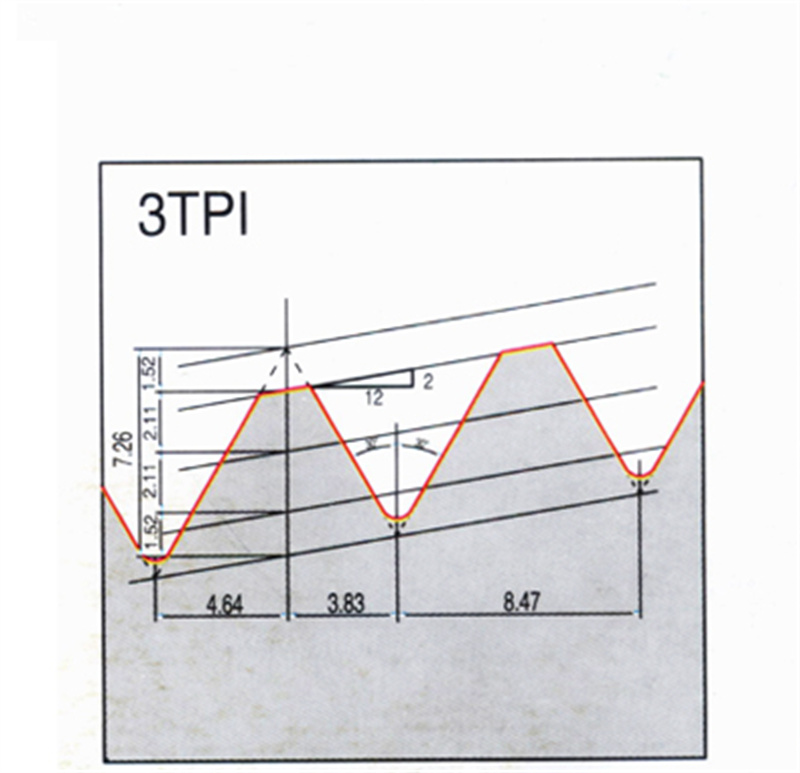

| 250 | 10 | 155T3N | 155.57 | 220.00 | 103.80 | <7 | 147.14 | 116.00 | 8.47 |

| 300 | 12 | 177T3N | 177.16 | 270.90 | 116.90 | 168.73 | 141.50 | ||

| 350 | 14 | 215T3N | 215.90 | 304.80 | 150.00 | 207.47 | 158.40 | ||

| 400 | 16 | 241T3N | 241.30 | 338.70 | 169.80 | 232.87 | 175.30 | ||

| 450 | 18 | 273T3N | 273.05 | 355.60 | 198.70 | 264.62 | 183.80 | ||

| 500 | 20 | 298T3N | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | ||

| 550 | 22 | 298T3N | 298.45 | 372.60 | 221.30 | 290.02 | 192.20 | ||

| Electrode | Miisaanka caadiga ah ee Ibta Naasaha | ||||||||

| Cabbirka Electrode Magaca ah | 3TPI | 4TPI | |||||||

| Dhexroor × Dhererka | T3N | T3L | T4N | T4L | |||||

| inji | mm | lbs | kg | lbs | kg | lbs | kg | lbs | kg |

| 14 × 72 | 350 × 1800 | 32 | 14.5 | - | - | 24.3 | 11 | - | - |

| 16 × 72 | 400 × 1800 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 16 × 96 | 400 × 2400 | 45.2 | 20.5 | 46.3 | 21 | 35.3 | 16 | 39.7 | 18 |

| 18 × 72 | 450 × 1800 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 18 × 96 | 450 × 2400 | 62.8 | 28.5 | 75 | 34 | 41.9 | 19 | 48.5 | 22 |

| 20 × 72 | 500 × 1800 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 84 | 500 × 2100 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 96 | 500 × 2400 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 20 × 110 | 500 × 2700 | 79.4 | 36 | 93.7 | 42.5 | 61.7 | 28 | 75 | 34 |

| 22 × 84 | 550 × 2100 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 22 × 96 | 550 × 2400 | - | - | - | - | 73.4 | 33.3 | 94.8 | 43 |

| 24 × 84 | 600 × 2100 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 96 | 600 × 2400 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| 24 × 110 | 600 × 2700 | - | - | - | - | 88.2 | 40 | 110.2 | 50 |

| Dhexroorka Electrode | inji | 8 | 9 | 10 | 12 | 14 |

| mm | 200 | 225 | 250 | 300 | 350 | |

| Daqiiqada Fududeynta | N·m | 200-260 | 300-340 | 400-450 | 550-650 | 800-950 |

| Dhexroorka Electrode | inji | 16 | 18 | 20 | 22 | 24 |

| mm | 400 | 450 | 500 | 550 | 600 | |

| Daqiiqada Fududeynta | N·m | 900-1100 | 1100-1400 | 1500-2000 | 1900-2500 | 2400-3000 |

Tilmaanta Rakibaadda

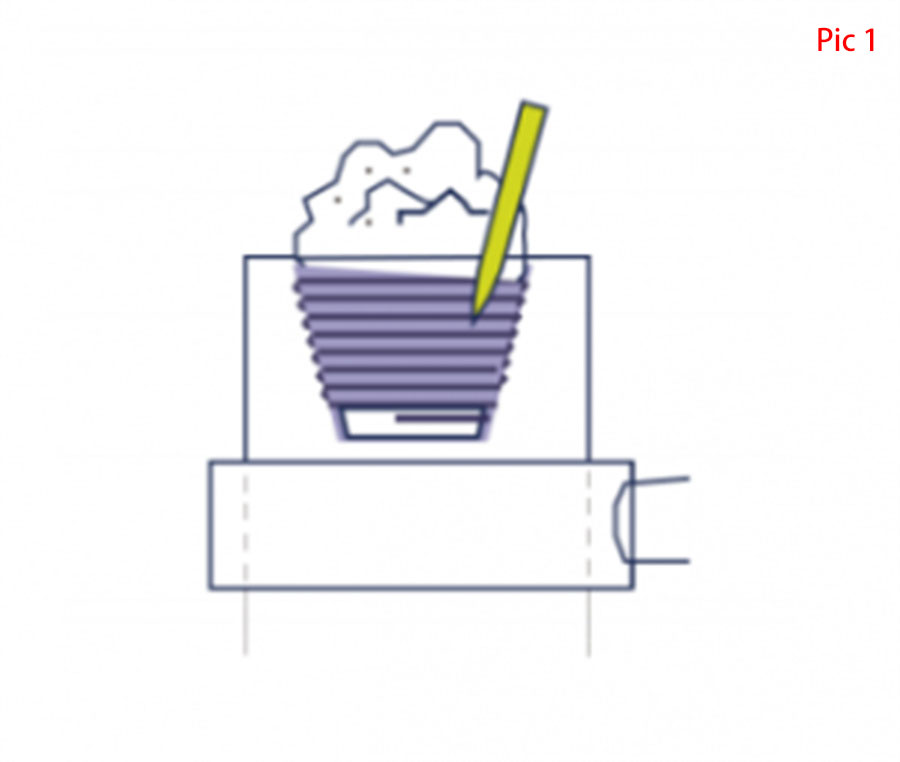

- Kahor intaadan rakibin ibta naaska graphite, nadiifi boodhka iyo wasakh dushiisa iyo godka korantada iyo ibta naaska oo leh hawo cufan;(fiiri sawirka1)

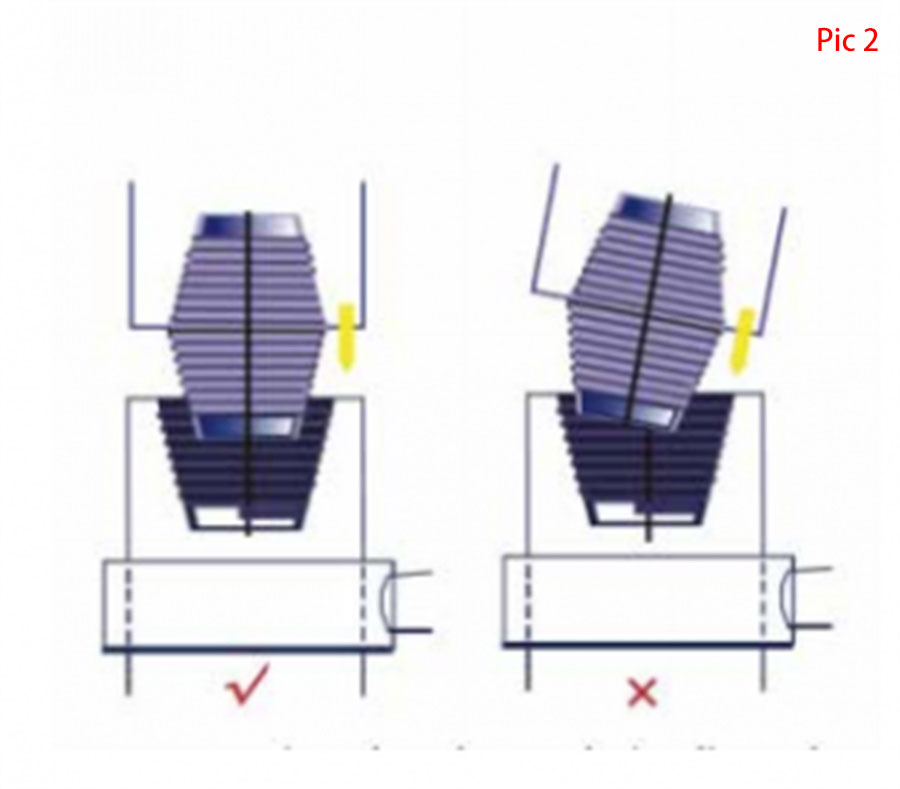

- Xariiqda dhexe ee ibta naaska graphite electrode waa inay ahaataa mid joogto ah inta lagu guda jiro laba qaybood oo elektaroonik ah oo isku xiran;(fiiri sawirka 2)

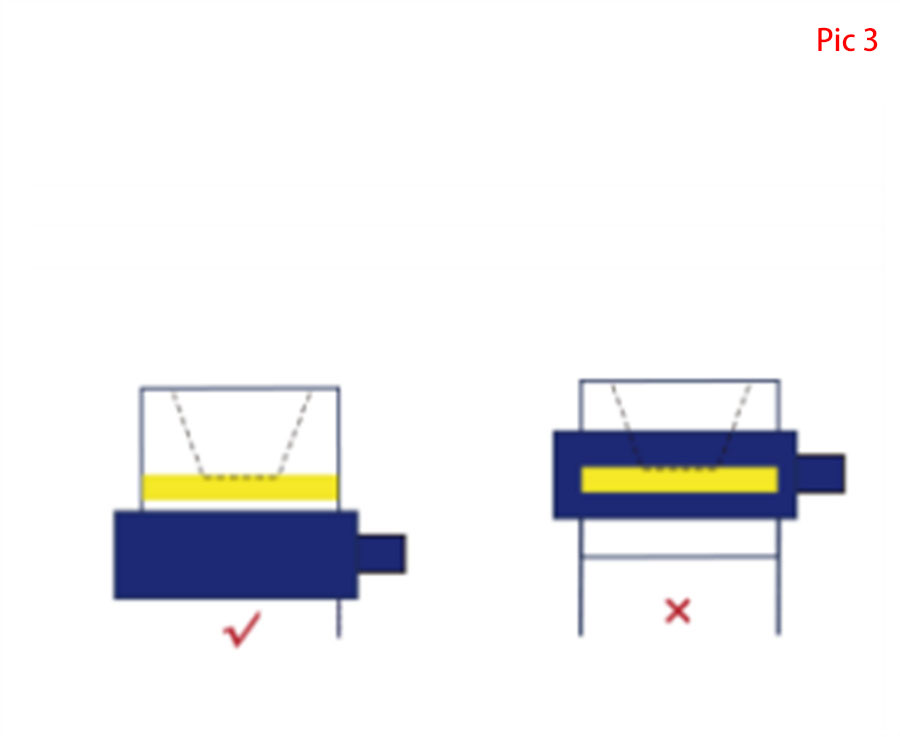

- Xakamaynta korantada waa in lagu hayaa meesha saxda ah: meel ka baxsan khadadka badbaadada ee dhamaadka sare;(fiiri sawirka 3)

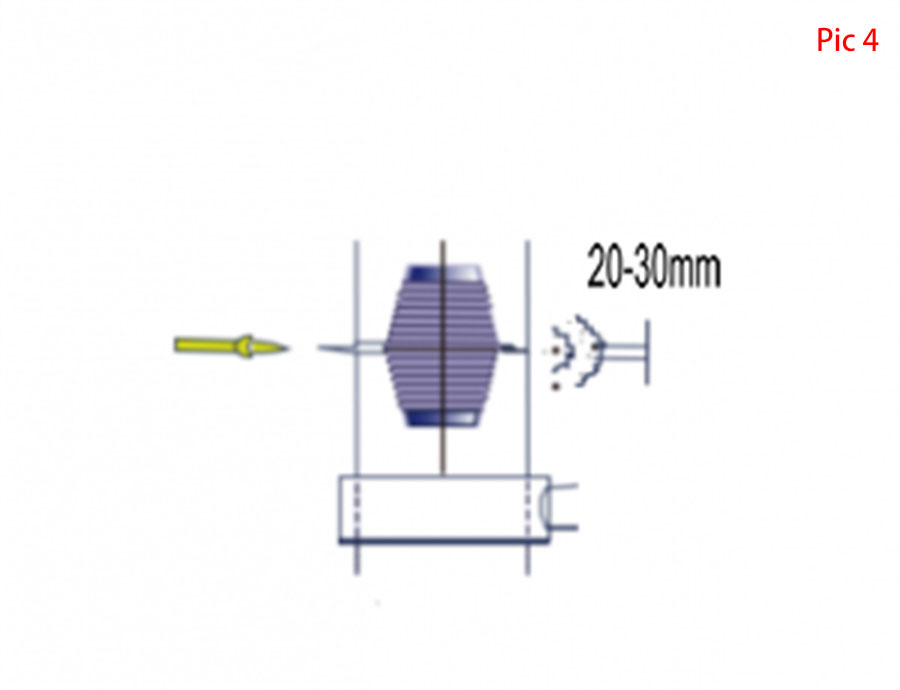

- Kahor intaadan adkayn ibta naaska, hubi in dusha ibta naaska ay nadiif yihiin iyada oo aan boodh ama wasakh lahayn.(fiiri sawirka 4)

Ibta graphite electrode waa qayb muhiim ah oo ka mid ah habka birta samaynta EAF.Tayada waxay si toos ah u saameynaysaa waxtarka iyo isku halaynta habka.Isticmaalka ibta naasaha oo tayo sare leh ayaa lagama maarmaan u ah ka hortagga shilalka korantada iyo in la hubiyo habka birta samaynta oo siman oo wax soo saar leh.Sida laga soo xigtay xogta warshadaha, in ka badan 80% shilalka korantada waxaa sababa ibta naasaha oo jaban iyo dhaqaaq dabacsan.Xulashada ibta saxda ah, arrimahan hoose waa in la tixgeliyaa.

- Dhaqdhaqaaqa kulaylka

- Iska caabin koronto

- Cufnaanta

- Awood makaanik

Marka la dooranayo ibta naaska graphite electrode, waxaa lama huraan ah in la tixgeliyo tayadooda, cabbirkeeda, qaabkeeda, iyo la jaanqaadida qalabka korantada iyo foornada.Xulashada ibta saxda ah, soosaarayaashu waxay hagaajin karaan tayada birta waxayna yareyn karaan kharashyada la xiriira hoos u dhaca iyo wax soo saarka liita.

Oo ay ku jiraan kuleylkeeda kulaylka, iska caabin koronto, cufnaanta, iyo xoogga farsamada.