Habka Wax-soo-saarka ee Graphite Electrode

Graphite electrode waa nooc ka mid ah heerkulka sare u adkaysta graphite walxaha soo saaray iyadoo la isticmaalayo coke batroolka, coke irbadda sida wadar ahaan, asphalt dhuxusha sida xidhe, ka dib markii taxane ah oo hababka sida isku dhafka ah, qaabaynta, dubay, quusin, graphitization iyo farsamaynta farsamada.

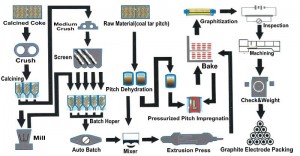

Habka ugu muhiimsan ee wax soo saarka ee electrode graphite waa sida soo socota:

(1) Calcination. Coke batroolka ama kookaha asphalt waxay u baahan yihiin in la been-abuuro, heerkulka calcination-kuna waa inuu gaaro 1300 ℃, si si buuxda looga saaro waxyaabaha kacsan ee ku jira alaabta ceeriin ee kaarboon, loona hagaajiyo cufnaanta dhabta ah, xoogga farsamada iyo korantada korantada.

(2) burburin, baaris, iyo maaddooyin. Walxaha cayriin ee kaarboonka la kariyey waa la jebiyey waxaana lagu baadhay qaybo wadareed oo cabbirka la cayimay ah, qayb ka mid ah kookaha ayaa lagu shiidayaa budo wanaagsan, isku dhafka qallalanna waxaa la isugu geynayaa si waafaqsan qaacidada.

(3) Isku qas. Xaaladda kululaynta, isku dhafka qallalan ee qiyaasta ee qaybo kala duwan ayaa lagu qasi karaa xiraha tirada, isku dhafan oo la cajiimay si loo farsameeyo koollada caagga ah.

(4) qaabaynta, hoos ficil cadaadiska dibadda (extrusion samaynta) ama hoos ficil gariir soo noqnoqda sare (samaynta gariir) si aad u cadaadi koollada galay qaab gaar ah iyo cufnaanta sare ee electrode cayriin (billet).

(5) Duubista. Electrode-ka cayriin waxa lagu dhejiyaa foorno duban oo gaar ah, budada kookaha ee macdanaha ah ayaa la buuxiyey oo lagu daboolay korantada ceeriin. Heerkulka sare ee wakiilka isku xidhka ee ku saabsan 1250 ℃, dubista kaarboonka ayaa la sameeyaa.

(6) Xumaan. Si loo hagaajiyo cufnaanta iyo xoogga farsamada ee alaabta korantada, korantada dubanaysa waxaa lagu shubaa qalabka tamarta sare leh, iyo asfalt wakiilka dareeraha ah ee dareeraha ah ayaa lagu cadaadiyaa godka hawada ee electrode. Ka dib dhexgalka, dubaydu waa in la sameeyaa hal mar. Marka loo eego shuruudaha waxqabadka badeecada, mararka qaarkood impregnation iyo dubista sare waa in lagu celiyaa 23 jeer.

(7) garaafaynta. Elektroodka kaarboonka ee la dubay waxaa lagu shubaa foornada garaafka, oo lagu daboolay walxaha dahaarka. Adigoo isticmaalaya habka kuleyliyaha ee koronto toos ah si loo soo saaro heerkulka sare, electrode kaarboon waxaa loo rogaa graphite electrode leh qaab dhismeedka crystal graphite heerkulka sare ee 2200 ~ 3000 ℃.

(8) mishiinada. Marka loo eego shuruudaha isticmaalka, garaafyada elektiroonigga ah ee bannaan ee leexashada, dusha sare ee dhammaadka siman iyo godadka isku xidhka isku xirka, iyo wadajirka isku xirka.

(9) Electrode graphite waa in si sax ah loo xirxiraa ka dib marka la gudbiyo baaritaanka oo loo diro isticmaalaha.

Waqtiga boostada: Jun-01-2023