Foornada Dhexroorka Yar ee Graphite Electrode ee foornada arc korantada ee birta iyo warshadaha abuurka

Qiyaasta Farsamada

Shaxda 1: Qiyaasta Farsamada ee Dhexroorka Yar ee Graphite Electrode

| Dhexroorka | Qayb | iska caabin | Xoog Jilicsan | Modulus yar | Cufnaanta | CTE | Dambas | |

| Inji | mm | μΩ·m | MPa | GPA | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Jaantuska 2: Awood Qaadashada Hadda ee Dhexroorka Yar ee Graphite Electrode

| Dhexroorka | Culayska Hadda | Cufnaanta Hadda | Dhexroorka | Culayska Hadda | Cufnaanta Hadda | ||

| Inji | mm | A | A/m2 | Inji | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Jaantuska 3: Cabirka korantada ee Garaafyada

| Dhexroor Magaca | Dhexroorka dhabta ah (mm) | Dhererka magacaaban | Dulqaad | |||

| Inji | mm | Max. | Min. | mm | Inji | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ± 100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ± 100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ± 100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ± 100 |

Codsiga ugu muhiimsan

- Kaalshiyaam carbide dhalaalaysa

- Wax-soo-saarka Carbordum

- Sifaynta Corundum

- Biraha naadirka ah ee dhalaalay

- Dhirta Ferrosilicon refractory

Gacan-siinta Tilmaamaha iyo Isticmaalka Qalabka Electrodes ee Graphite

1.Ka saar daboolka difaaca ee daloolka cusub ee korantada, hubi in dunta godka korantada ay dhammaatay iyo in duntu aanay dhamaystirnayn, la xidhiidh injineerada xirfadlayaasha ah si loo go'aamiyo in korantada la isticmaali karo;

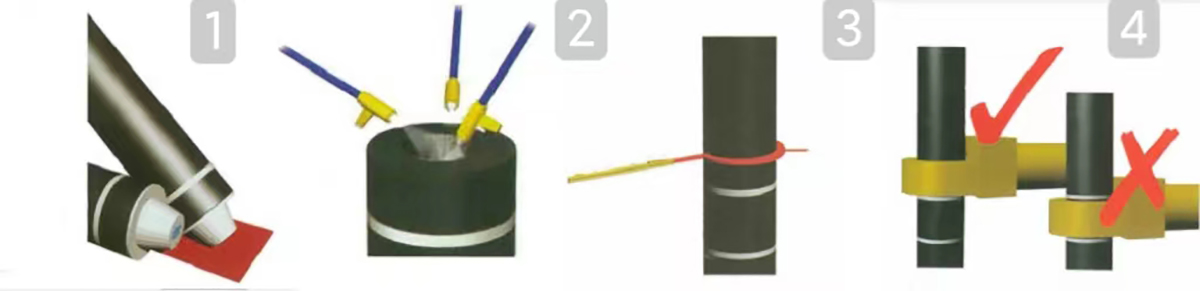

2. Ku marooji hanger-ka korantada godka korantada ee hal cidhif, oo dhig barkin jilicsan hoostiisa cidhifka kale ee korantada si aad isaga ilaaliso in ay waxyeeleyso isku dhafka korantada;(eeg sawirka1)

3.Isticmaal hawo cufan si aad ugu afuufo boodhka iyo sundries dusha sare iyo dalool ee electrode-ka xidhiidhinaya, ka dibna nadiifi dusha iyo xidhiidhiyaha ee electrode cusub, ku nadiifi burush;(eeg pic2)

4. Kor u qaad korantada cusub ee ka sarreysa korantada sugaysa si ay ula jaanqaado godka korantada oo si tartiib ah u dhaco;

5.Isticmaal qiimaha qulqulka saxda ah si aad si sax ah u quful electrode;(eeg sawirka 3)

6. Haysta xajinta waa in la dhigaa meel ka baxsan khadka digniinta.(fiiri pic4)

7.In muddada sifaynta, waa ay fududahay in la sameeyo electrode khafiif ah oo sababa jabka, wadajir dhici off, kordhiyo isticmaalka electrode, fadlan ha isticmaalin electrodes si kor loogu qaado content carbon.

8.Due in alaabta ceeriin kala duwan loo isticmaalo by saaraha kasta iyo habka wax soo saarka, sifooyinka jireed iyo kiimiko ee electrodes iyo kala-goysyada soo saaraha kasta. Marka la isticmaalo, xaaladaha guud, Fadlan ha isku darin isticmaalka korantada iyo kala-goysyada ay soo saaraan warshado kala duwan.