Graphite Electrode waxay u isticmaashaa Corundum Sifaynta Foornada Arc ee Korontada

Qiyaasta Farsamada

Shaxda 1: Qiyaasta Farsamada ee Dhexroorka Yar ee Graphite Electrode

| Dhexroorka | Qayb | iska caabin | Xoog Jilicsan | Modulus yar | Cufnaanta | CTE | Dambas | |

| inch | mm | μΩ·m | MPa | GPA | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Jaantuska 2: Awood Qaadashada Hadda ee Dhexroorka Yar ee Graphite Electrode

| Dhexroorka | Culayska Hadda | Cufnaanta Hadda | Dhexroorka | Culayska Hadda | Cufnaanta Hadda | ||

| inch | mm | A | A/m2 | inch | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Jaantuska 3: Cabirka korantada ee Garaafyada

| Dhexroor Magaca | Dhexroorka dhabta ah (mm) | Dhererka magacaaban | Dulqaad | |||

| inch | mm | Max. | Min. | mm | inch | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ± 100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ± 100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ± 100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ± 100 |

Codsiga ugu muhiimsan

- Kaalshiyaam carbide dhalaalaysa

- Wax-soo-saarka Carbordum

- Sifaynta Corundum

- Biraha naadirka ah ee dhalaalay

- Dhirta Ferrosilicon refractory

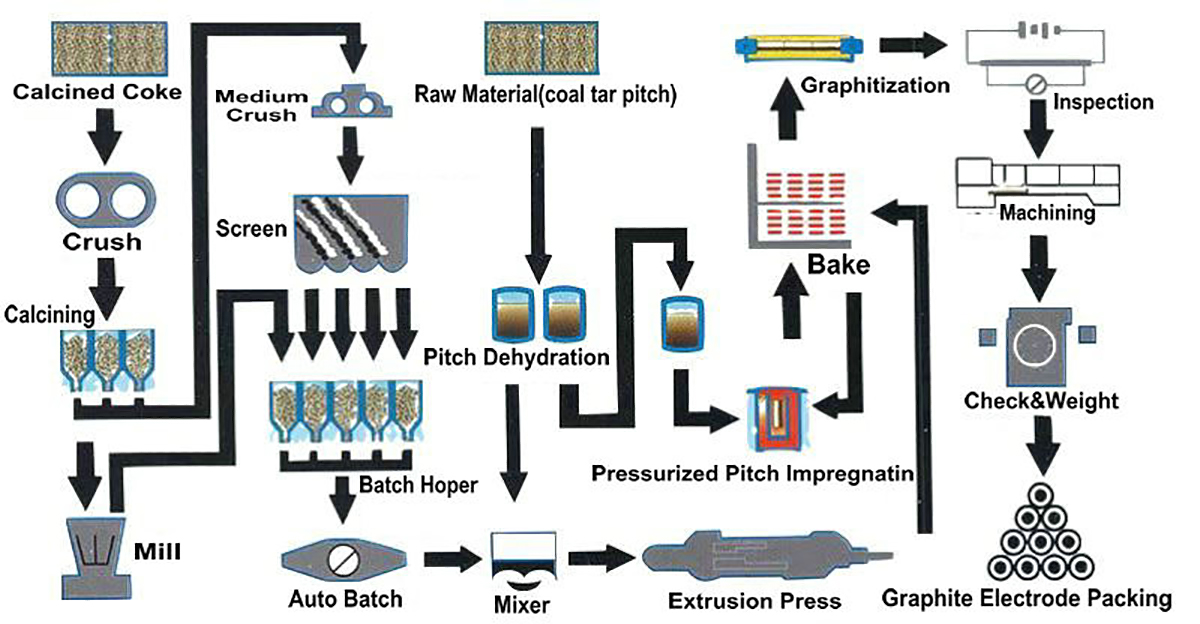

Habka Wax Soo Saarka ee RP Graphite Electrode

Faa'iidooyinka Gufan

1. Waxaa laga sameeyay qalab tayo sare leh oo garaaf ah, electrodes-ka garaafyada dhexroorka yar ee dhexroorka ah ayaa loo dhisay si ay u adkeystaan heerkulka aadka u daran waxayna bixiyaan koronto heer sare ah.Tani waxay hubinaysaa habka dhalaalidda xasilloon oo hufan, taasoo keentay tayada badeecada sare iyo isticmaalka tamarta oo yaraada.

2. Cabbirka yar ee korantadaani waxay u oggolaaneysaa in si sax ah loo xakameeyo habka dhalaalka, taas oo ka dhigaysa mid ku habboon codsiyada u baahan saxnaanta sare iyo natiijooyinka wanaagsan.Haddi aad soo saarayso alloys ama sifaynta biraha, electrodes-kayaga ayaa kaa caawin doona inaad ku guulaysato natiijada la rabo si sax ah oo aan la barbar dhigi karin.

3. Electrodes garaafyada dhexroorka yar ee dhexroorkayaga ah waxay ku habboon yihiin warshado badan oo kala duwan, oo ay ku jiraan wax soo saarka birta, farsamaynta kiimikada, iyo tuurista birta.Si kastaba ha ahaatee baaxadda hawlgalkaaga, korantadayada waa la habeyn karaa si ay u buuxiyaan shuruudahaaga gaarka ah.

4. In wax soo saarka birta, our electrodes garaafyada dhexroor yar yar waxaa loo isticmaalaa in foornooyinka arc koronto, halkaas oo ay ka ciyaaraan door muhiim ah in wax soo saarka ee bir tayo sare leh.Xajmigooda yar ayaa u oggolaanaya in si sax ah loo xakameeyo habka dhalaalka, hubinta natiijooyinka joogtada ah iyo yaraynta qashinka.

5. Marka la isticmaalayo kiimikaad, electrodes-kayadu waxay lagama maarmaan u yihiin soo saarista kaarbiid-ka calcium iyo sifaynta carborundum.Nidaamyadani waxay u baahan yihiin xakamaynta heerkulka saxda ah, kaas oo korantadayadu si sax ah ugu bixiyaan.

6. Sibidhka birta ah, electrodes garaafyada dhexroorka yar ee dhexroorka yari waxa loo isticmaalaa dhalaalinta biraha dhifka ah iyo dhirta Ferrosilicon.Dhaqdhaqaaqa sare ee garaafka wuxuu u oggolaanayaa dhalaalid hufan oo biraha ah, taasoo keentay wareegyo wax soo saar degdeg ah iyo wax soo saarka guud ee sare.