HP24 Graphite Carbon Electrodes Dia 600mm Foornada Arc Koronto

Qiyaasta Farsamada

| Halbeegga | Qayb | Unug | HP 600mm(24 ") Xog |

| Dhexroor Magaca | Electrode | mm (inji) | 600 |

| Dhexroorka ugu badan | mm | 613 | |

| Dhexroor Min | mm | 607 | |

| Dhererka magacaaban | mm | 2200/2700 | |

| Dhererka ugu badan | mm | 2300/2800 | |

| Dhererka min | mm | 2100/2600 | |

| Cufnaanta Hadda | KA/cm2 | 13-21 | |

| Awood Qaadashada Hadda | A | 38000-58000 | |

| Iska caabin gaar ah | Electrode | μΩm | 5.2-6.5 |

| Ibta naaska | 3.2-4.3 | ||

| Xoog Jilicsan | Electrode | Mpa | ≥10.0 |

| Ibta naaska | ≥22.0 | ||

| Modulka dhalinyarada | Electrode | Gpa | ≤12.0 |

| Ibta naaska | ≤15.0 | ||

| Cufnaanta Bulk | Electrode | g/cm3 | 1.68-1.72 |

| Ibta naaska | 1.78-1.84 | ||

| CTE | Electrode | ×10-6/℃ | ≤2.0 |

| Ibta naaska | ≤1.8 | ||

| Waxyaabaha Dambaska ah | Electrode | % | ≤0.2 |

| Ibta naaska | ≤0.2 |

FIIRO GAAR AH: Shuruudaha gaarka ah ee cabbirka waa la bixin karaa.

Sida loo waafajiyo Graphite Electrode iyo Foornada Arc Korontada

Electrodes-ka graphite waa qaybo muhiim ah oo ka mid ah habka birta samaynta ee Foornada Korontada (EAF). Si kastaba ha ahaatee, qiimaha habka birta samaynta waxaa saameeya oksidation electrode, sublimation, kala diri, spalling, iyo jebinta. Warka wanaagsani waa in xulashada graphite electrode, isticmaalka, iyo dayactirka ay si wax ku ool ah u yareeyn karto isticmaalka korantada. Maqaalkan, waxaan ka wada hadli doonaa sida loo doorto graphite electrode saxda ah iyo sida loo ilaaliyo si sax ah si aad u hesho faa'iidada ugu badan ee maalgashigaaga.

Tilmaamaha

Isbarbardhigga awoodda foornada korontada, culeyska korantada beddelka iyo cabbirka korantada.

| Awoodda foornada | Dhexroorka Gudaha (m) | Awood beddelka (MVA) | Dhexroorka Electrode ee Graphite (mm) | ||

| UHP | HP | RP | |||

| 10 | 3.35 | 10 | 7.5 | 5 | 300/350 |

| 15 | 3.65 | 12 | 10 | 6 | 350 |

| 20 | 3.95 | 15 | 12 | 7.5 | 350/400 |

| 25 | 4.3 | 18 | 15 | 10 | 400 |

| 30 | 4.6 | 22 | 18 | 12 | 400/450 |

| 40 | 4.9 | 27 | 22 | 15 | 450 |

| 50 | 5.2 | 30 | 25 | 18 | 450 |

| 60 | 5.5 | 35 | 27 | 20 | 500 |

| 70 | 6.8 | 40 | 30 | 22 | 500 |

| 80 | 6.1 | 45 | 35 | 25 | 500 |

| 100 | 6.4 | 50 | 40 | 27 | 500 |

| 120 | 6.7 | 60 | 45 | 30 | 600 |

| 150 | 7 | 70 | 50 | 35 | 600 |

| 170 | 7.3 | 80 | 60 | --- | 600/700 |

| 200 | 7.6 | 100 | 70 | --- | 700 |

| 250 | 8.2 | 120 | --- | --- | 700 |

| 300 | 8.8 | 150 | --- | --- | |

Tilmaamaha Gacan-siinta iyo Isticmaalka

- 1.Ka saar daboolka difaaca ee daloolka cusub ee korantada, hubi in dunta godka korantada ay dhammaatay iyo in duntu aanay dhamaystirnayn, la xidhiidh injineerada xirfadlayaasha ah si loo go'aamiyo in korantada la isticmaali karo;

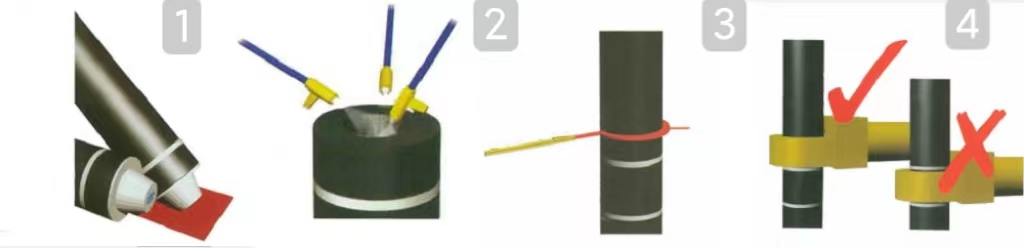

- 2. Ku xidh daboolka korantada godka korantada ee hal cidhif, oo dhig barkin jilicsan hoostiisa cidhifka kale ee korantada si aad isaga ilaaliso in ay dhaawacdo isku dhafka korantada; (fiiri sawirka1)

- 3.Isticmaal hawo cufan si aad u afuufo boodhka iyo sundries dusha sare iyo dalool ee electrode isku xidha, ka dibna nadiifi dusha iyo xidhiidhiyaha ee electrode cusub, ku nadiifi burush; (fiiri sawirka 2)

- 4. Kor u qaad korantada cusub ee ka sarreysa korantada sugaysa si ay ula jaanqaado godka korantada oo si tartiib ah u dhaco;

- 5. Isticmaal qiimaha torque saxda ah si aad si sax ah u quful electrode; (fiiri sawirka 3)

- 6.Clamp holde waa in la dhigaa meel ka baxsan khadka digniinta. (fiiri sawirka 4)

- 7.In muddada sifaynta, waa ay fududahay in la sameeyo electrode khafiif ah oo sababa jabka, wadajir dhici off, kordhiyo isticmaalka electrode, fadlan ha isticmaalin electrodes si kor loogu qaado content carbon.

- 8.Due in alaabta ceeriin kala duwan loo isticmaalo by saaraha kasta iyo habka wax soo saarka, sifooyinka jireed iyo kiimiko ee electrodes iyo kala-goysyada soo saaraha kasta. Marka la isticmaalo, xaaladaha guud, Fadlan ha isku darin isticmaalka korantada iyo kala-goysyada ay soo saaraan warshado kala duwan.