Cufnaanta Sare ee Foornada Dhexroorka Yar ee Graphite Electrode ee Foornada Qarxa Foornada Ladle

Qiyaasta Farsamada

Shaxda 1: Qiyaasta Farsamada ee Dhexroorka Yar ee Graphite Electrode

| Dhexroorka | Qayb | iska caabin | Xoog Jilicsan | Modulus yar | Cufnaanta | CTE | Dambas | |

| Inji | mm | μΩ·m | MPa | GPA | g/cm3 | ×10-6/℃ | % | |

| 3 | 75 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 4 | 100 | Electrode | 7.5-8.5 | ≥9.0 | ≤9.3 | 1.55-1.64 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 6 | 150 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 8 | 200 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 9 | 225 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

| 10 | 250 | Electrode | 7.5-8.5 | ≥8.5 | ≤9.3 | 1.55-1.63 | ≤2.4 | ≤0.3 |

| Ibta naaska | 5.8-6.5 | ≥16.0 | ≤13.0 | ≥1.74 | ≤2.0 | ≤0.3 | ||

Jaantuska 2: Awood Qaadashada Hadda ee Dhexroorka Yar ee Graphite Electrode

| Dhexroorka | Culayska Hadda | Cufnaanta Hadda | Dhexroorka | Culayska Hadda | Cufnaanta Hadda | ||

| Inji | mm | A | A/m2 | Inji | mm | A | A/m2 |

| 3 | 75 | 1000-1400 | 22-31 | 6 | 150 | 3000-4500 | 16-25 |

| 4 | 100 | 1500-2400 | 19-30 | 8 | 200 | 5000-6900 | 15-21 |

| 5 | 130 | 2200-3400 | 17-26 | 10 | 250 | 7000-10000 | 14-20 |

Jaantuska 3: Cabirka korantada ee Garaafyada

| Dhexroor Magaca | Dhexroorka dhabta ah (mm) | Dhererka magacaaban | Dulqaad | |||

| Inji | mm | Max. | Min. | mm | Inji | mm |

| 3 | 75 | 77 | 74 | 1000 | 40 | -75~+50 |

| 4 | 100 | 102 | 99 | 1200 | 48 | -75~+50 |

| 6 | 150 | 154 | 151 | 1600 | 60 | ± 100 |

| 8 | 200 | 204 | 201 | 1600 | 60 | ± 100 |

| 9 | 225 | 230 | 226 | 1600/1800 | 60/72 | ± 100 |

| 10 | 250 | 256 | 252 | 1600/1800 | 60/72 | ± 100 |

Codsiga ugu muhiimsan

- Kaalshiyaam carbide dhalaalaysa

- Wax-soo-saarka Carbordum

- Sifaynta Corundum

- Biraha naadirka ah ee dhalaalay

- Dhirta Ferrosilicon refractory

Gacan-siinta Tilmaamaha iyo Isticmaalka Qalabka Electrodes ee Graphite

1.Isticmaal qalabka gaarka ah ee kor u qaadida si aad nolosha ugu noolaato graphite electrode iska ilaali in ay waxyeelo gaarto inta lagu jiro gaadiidka.(eeg sawirka1)

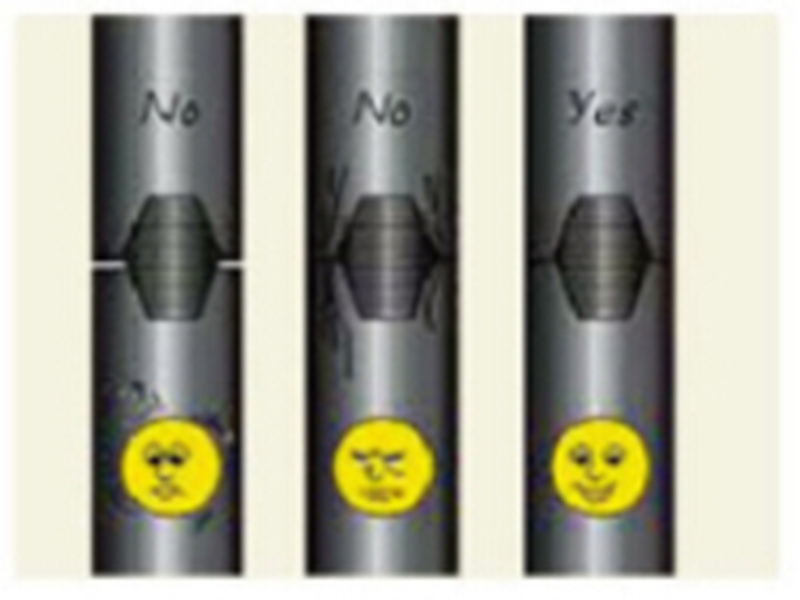

2.Graphite electrode waa in laga fogaadaa in roobku qoyan ama qoyan, barafka, ha ahaado mid engegan.(eeg sawirka2)

3. Si taxadar leh u hubi isticmaalka ka hor, hubi in xadhigga iyo dunta ibta naaska ay ku habboon yihiin isticmaalka, oo ay ku jiraan kormeerka garoonnada, furaha.(eeg sawirka pic3)

4. Ku nadiifi dunta ibta naaska iyo saldhigyada hawo cadaadisaysan (eeg sawirka 4)

Isticmaalka ka hor, electrode graphite waa in lagu qalajiyaa foornada, heerkulka qalajinta waa in ka yar 150 ℃, wakhtiga la qalajiyey waa in ka badan 30saacadood.(eeg sawirka 5)

6.Graphite electrode waa in lagu xidhaa si adag oo toos ah iyadoo la raacayo qulqulka adkaynta ku haboon.(eeg sawirka6)

7. Si aad uga fogaato jebinta korantada graphite, dhig qaybta weyn ee booska hoose iyo qayb yar oo ka mid ah booska sare.